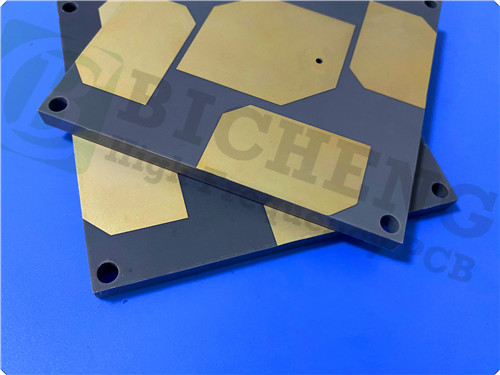

F4BTMS615 High Frequency PCB - 2-Layer Rigid PCB with HASL Finish

1.F4BTMS Introduction

The F4BTMS series represents an advanced iteration of the F4BTM series, featuring significant innovations in material formulation and manufacturing techniques. This upgraded material incorporates a substantial amount of ceramics and is reinforced with ultra-thin, ultra-fine glass fiber cloth. These enhancements lead to marked improvements in performance and a wider range of dielectric constants, making it a high-reliability option for aerospace applications, capable of replacing similar foreign products.

By integrating a small quantity of ultra-thin glass fiber cloth with a large amount of uniformly distributed special nano-ceramics mixed with polytetrafluoroethylene resin, the adverse effects of glass fiber on electromagnetic wave propagation are minimized. This approach reduces dielectric loss, enhances dimensional stability, and decreases the anisotropy in the X/Y/Z directions. It also expands the usable frequency range, improves electrical strength, and boosts thermal conductivity. Furthermore, the material features a low thermal expansion coefficient and stable dielectric temperature characteristics.

The F4BTMS series includes RTF low roughness copper foil as a standard feature, which reduces conductor loss and provides excellent peel strength. It is compatible with both copper and aluminum bases.

2. Features of F4BTMS615

- Dielectric constant (Dk) of 6.15 at 10 GHz

- Dissipation factor of 0.0020 at 10 GHz and 0.0023 at 20 GHz

- Coefficient of Thermal Expansion (CTE): 10 ppm/°C in the X-axis, 12 ppm/°C in the Y-axis, 40 ppm/°C in the Z-axis, over a range of -55°C to 288°C

- Low thermal coefficient of Dk at -96 ppm/°C, from -55°C to 150°C

- High thermal conductivity of 0.67 W/mK

- Moisture absorption rate of 0.1%

3. PCB Stackup: 2-layer rigid PCB

The stackup consists of:

- Copper Layer 1: 35 µm

- F4BTMS615 Core: 5.08 mm (200 mil)

- Copper Layer 2: 35 µm

4. PCB Construction Details

- Board dimensions: 92.32 mm x 31.5 mm (1 piece), with a tolerance of ±0.15 mm

- Minimum trace/space: 5/5 mils

- Minimum hole size: 0.5 mm

- No blind vias are present.

- Finished board thickness: 5.2 mm

- Finished copper weight: 1 oz (1.4 mils) for outer layers

- Via plating thickness: 20 µm

- Surface finish: Hot Air Soldering Level (HASL)

- Top silkscreen: None

- Bottom silkscreen: None

- Top solder mask: None

- Bottom solder mask: None

- 100% electrical testing conducted prior to shipment

5. PCB Statistics

- Total components: 20

- Total pads: 35

- Through-hole pads: 21

- Top SMT pads: 14

- Bottom SMT pads: 0

- Vias: 37

- Nets: 2

6. Type of Artwork Supplied

Gerber RS-274-X

7. Quality Standard

IPC-Class-2

8. Availability

Available worldwide

9. Typical Applications

- Aerospace equipment, including space and cabin systems

- Microwave and RF applications

- Radar and military radar systems

- Feed networks

- Phase-sensitive antennas and phased array antennas

- Satellite communications and more.